Product Center

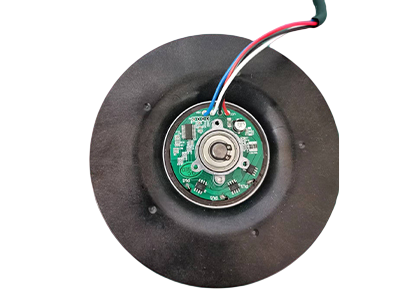

Ouck mainly produces various types of motors, generators, control drives and industrial automation products.

Strive to be the leader of stepper motors and synchronous motors in the global refrigeration/sanitary ware industry

Changzhou Ouck Electric Co., Ltd. is an enterprise integrating scientific research, development and production. Has advanced professional production equipment and mature technology, more professional management and technical personnel. The company covers an area of 40,000 square meters and a building area of 58,000 square meters. There are more than 1,200 employees and 190 management personnel (including 58 engineering and technical personnel and 65 quality personnel). The company has obtained ISO9001 quality system certification, ISO14001 environmental system certification, ccc certification, VDE certification, TUV certification and UL certification (E319020).

View MoreOukai was founded in

Existing employees

Annual production of stepping and synchronous motors

Honor

All products are of good quality, all in line with relevant national standards, the company has won the favor of more customer groups!

View More

Partners

The company's main customers: Midea, Gree, Haier, LG, Samsung, Panasonic, Kohler, Elite, Oulingbao, Mitsubishi Heavy Industries, Japan TOTO, Jiumu, Ecovacs, Xiaomi, Hengjie, etc.

Latest News

Creating a New Ecosystem for the Industry

2022-03-02

What is the function of the stepper motor? This is generally a question that students who are new to the stepper motor, or who are still reading, may ask, because the principle of the stepper motor is to convert the pulse signal into a linear displacement or angular displacement motor.

View DetailsWhat is the function of the stepper motor? This is generally a question that students who are new to the stepper motor, or who are still reading, may ask, because the principle of the stepper motor is to convert the pulse signal into a linear displacement or angular displacement motor.

A stepping motor is an electromechanical device that directly converts electrical pulses into mechanical motion. By controlling the sequence, frequency and quantity of electrical pulses applied to the motor coil, the steering, speed and rotation angle of the stepping motor can be controlled. Without the use of a closed-loop feedback control system with position sensing, a simple and low-cost open-loop control system composed of a stepper motor and its matching driver can achieve precise position and speed control.

Stepper motor is an open-loop control element stepper motor that converts electrical pulse signals into angular displacement or linear displacement. By controlling the sequence, frequency and quantity of electrical pulses applied to the motor coil, the steering

In industrial automation, stepper motors are widely used. For example, industrial robots, 3D printers, computer hard drives, etc. all have stepper motors. The particularity of the stepper motor is that it can control the angular position of the rotor without the need for sensors to control the position, so it is an open-loop control system. Similar to the DC brushless motor, they all rotate by controlling the energization sequence of the coil to generate an interactive force between the magnets.